ASIC vs FPGA: Case Studies on Prototyping, Design, and Implementation

In this fast-moving world of electronics and embedded systems, it’s time to face one critical decision: ASIC or FPGA? This choice can heavily affect the development cycle, cost, performance, and scalability of the project. We will describe the pros and cons of each technology along with cases of prototyping, design, and implementation of one versus the other.

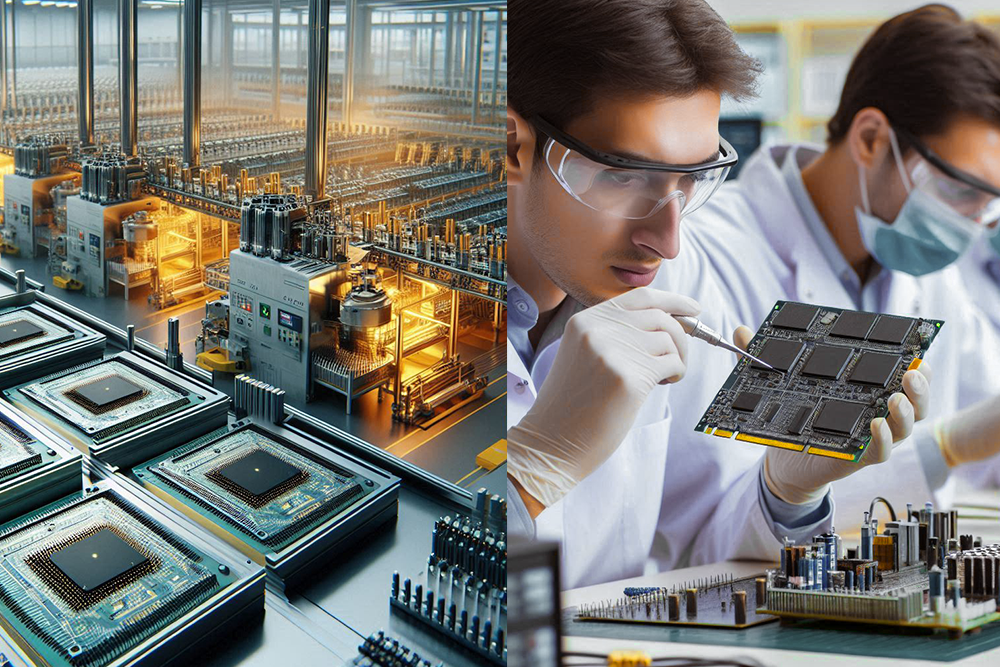

ASIC vs. FPGA: Basic Differences

ASIC is a semi-custom chip designed and optimized for an application-specific use case, which cannot be changed once it has been manufactured. It represents the acme of high-performance, low-power, and cost-effective applications in large quantities but takes much more time and money to develop because of NRE.

On the other hand, FPGA is a reconfigurable silicon chip wherein, after manufacturing, one can change the logic in hardware by the designer. This reusability of design makes FPGAs ideal for prototyping and iterative designs but tend to consume more power and have lesser performance as compared to ASICs.

Prototyping: Speed vs. Customization

- FPGA for Rapid Prototyping

Another of the main reasons why designers choose FPGA for prototyping is the rapid development cycle. With this type of FPGA, implementing, testing, and modifying designs in the hands of engineers is fast. This especially becomes very crucial during markets where the time-to-market factor is greatly considered. For instance, in the automotive domain, firms working on ADAS deploy FPGA use during prototype development stages for prototype validation only to prove the algorithm of sensor fusion and machine learning. Such firms can quickly iterate designs and update the logic based on feedback from both functional and performance assessments with FPGAs.

B. ASIC for Prototype Validation

While FPGA is suitable for early prototypes, companies often switch to ASIC for final validation. This occurs primarily as the process enters mass production. For example, in consumer electronics, ASIC chips are integrated once the FPGA prototype has proven viable. From this, manufacturing companies have the chip development benefit of ASIC with little to no risks at later design stages.

Design Criteria: Power, Performance, and Flexibility

- Power Dissipation

Hence, for such projects which consider power efficiency, ASIC generally has the upper hand. For example, one may look at a mobile communications field. In this regard, there are devices like smartphones whose chips are supposed to consume less power while performing complex computations. On account of the lack of uniformity of applications, an ASIC that has been designed for a narrow application can be optimized for minimal power consumption.

However, FPGAs are mainly utilized in applications that do not so severely restrict power, such as data centres and networking equipment. There, the flexibility to modify hardware logic with changing requirements outweighs the larger power consumption of FPGAs.

- Performance Requirements

Regarding performance, ASIC shines when low latency with high throughput is a necessity – as, for example, in cryptocurrency mining or HFT (high-frequency trading). For instance, ASIC-based solutions have been used in Bitcoin mining because no other form of computing is as effective as an ASIC at executing specific hash algorithms.

Conversely, FPGAs tend to be more used in real-time processing applications, such as encoding video or telecommunications. For such purposes, the parallel processing capability of FPGA is a significant advantage, allowing for an excellent implementation for those tasks where capabilities can be distributed across several hardware blocks.

Implementation Challenges: Costs, Tools, and Risks

- Development Costs

One of the most limiting factors for ASIC adoption relates to high upfront costs. ASIC design and verification processes entail a huge investment in design, verification, and manufacturing processes. It results in NRE costs, which include the cost of making the custom chip. Such can run into millions of dollars, so ASICs are best suited to projects that will produce in volumes that justify the upfront cost.

On the other side, FPGA costs are significantly lower, especially in the early stages of development. No expensive silicon fabrication is required for companies to start testing their designs at a fraction of the cost so FPGA is preferred for low-volume or highly experimental projects.

B. Toolsets and Ecosystem

ASIC and FPGA both supply robust toolsets for development environments. FPGA design is typically carried out in either VHDL or Verilog, hardware description languages, along with proprietary tools from Xilinx and Intel, among others. These enable designers to simulate and synthesize quickly and help accelerate the cycle of development. ASICs are more specialized and hence require collaboration with the foundries and highly advanced simulation tools for tapeout. Companies undertaking ASIC projects spend a lot on EDA (Electronic Design Automation) tools as they do not want to start chip manufacture with flawed design.

C. Risk Management

This makes FPGA a relatively safer option for projects with vague specifications. Companies operating in fast-moving industries, such as IoT or AI accelerators, might begin with FPGA to avoid the risk of possibly committing too early to a fixed ASIC design.

However, where there are well-defined requirements and the market is large in terms of the likely number of units produced, the advantages in terms of better performance and lower unit cost may make the risks associated with commitment to a single design seem worthwhile.

Case Study 1: Prototyping Medical Devices

Scenario:

For a company that would like to venture into the development of a next-gen ultrasonic flow diagnostic system for medical devices, the hardware design of our own Safey Medical Devices project faces scalability problems from prototypes to mass production. The product needs to be made effective in handling gas flow rates with high precision.

Decision Points:

- Prototyping Stage: Almost right from day one, the company was utilizing an FPGA to give room for speedy testing and design changes. The use of an FPGA accommodated changes in the signal processing algorithm and the analog-to-digital conversion with minimal delay and cost.

- Design Finalization and Production: Once the design was stable, the move to an ASIC became necessary. The lower per-unit cost of ASICs in mass production made them the obvious choice, especially considering the budget constraints per chip for large-scale medical device deployment.

Conclusion:

FPGAs were used in the prototyping phases where flexibility was required, but for mass deployment in ASIC technology, it would provide better cost and performance, as promised by the manufacturer.

Case Study 2: Cryptography and Quantum Key Distribution (QKD)

Scenario:

In the case of cryptography post-quantum, like FPGA-based post-processing for Quantum Key Distribution (QKD), speed and agility become key parameters. In such a system, high-speed error correction and key sifting have to be carried out without compromising security integrity.

Decision Points:

- Prototyping and Research: In pioneering research into CVQKD, an FPGA supplies reconfigurability for experimentation with different cryptographic algorithms and security protocols. FPGAs are particularly useful because the technology is evolving all the time, and allowing continuous refinement. The development board, Microchip Technology’s PolarFire SoC Icicle Kit, also provides high-performance processing, which is combined with improved energy efficiency, thereby ideal for use in cryptography.

- Implementation: Optimizing the protocol and hardware components, an ASIC is now feasible to be deployed in a production-ready system, with enhanced security guarantees and optimal performance for post-quantum encryption.

Conclusion:

Although FPGAs shine in cryptographic applications in the experimentation and prototyping phase, for large-scale deployment with high assurance, performance and reliability are necessary characteristics that ASICs offer.

Case Study 3: Consumer Electronics-AI Accelerators

Scenario:

A new tech startup is developing an AI accelerator for real-time processing of images. The application that this product is designed for requires low latency as well as the ability to implement complex neural networks.

Decision Points:

- Prototyping Stage: The company proceeds with an FPGA because it can implement and evolve various neural network architectures quickly. FPGAs have advantages in terms of multiple parallel processing streams, especially useful in image recognition where the streams come one after another.

- Scaling up: Once the product moves out of prototype into commercial deployment, ASICs are way ahead. Because of their highly demanding nature in AI applications, optimized power consumption and higher processing speeds become an ultimate requirement in an ASIC. The time to develop may be longer, but there is always a reason to put more money in terms of performance improvement by a commercial AI product.

Conclusion:

The FPGA aspect was crucial for fast iteration to development, and the ASIC was essential for delivering a highly performing product at the end, hence critical for competitiveness in the AI market.

Important Points While Choosing Between ASIC and FPGA

- Development Cycle: In the early stages of development, the design has to change rapidly, therefore FPGAs are perfect. However, ASICs have longer cycles concerning design but help in mass production when the design is already complete.

- Cost: In the early stages of development, the design has to change rapidly, therefore FPGAs are perfect. However, ASICs have longer cycles concerning design but help in mass production when the design is already complete.

- Performance and Power Efficiency: ASICs more often than not outperform FPGAs in terms of power consumption and speed. However, FPGAs are gaining due to the newer architectures and nowadays are significantly used in high-performance applications such as 5G and AI.

- Flexibility and Reconfigurability: FPGAs are programmable and hence subject to changes after deployment. They give support for after-deployment updates and more flexibility. ASICs are engraved into stone once manufactured, offering no flexibility for design changes.

Conclusion: A Tug of War between Flexibility and Efficiency

It is only on a project-to-project basis that ASIC or FPGA can be selected as and when required – speed of development, cost, performance, and scalability. The tremendous advantages that FPGAs provide during prototyping as well as in applications requiring after-deployment flexibility give them an edge over ASICs. However, in high-volume, performance-critical applications, ASICs are still the gold standard.

Thus, understanding these trade-offs is critical for engineers, as these move in exciting areas ranging from medical devices to quantum cryptography and AI accelerators. Inevitably, the choice will become even more correct as the nature of tomorrow’s designs evolves even further, with both FPGA and ASIC technologies under constant progress