What Is Smart Manufacturing and How Can It Transform Your Operations?

The new wave of change in the high world of technology is actually smart manufacturing, which is happening quickly today. The increasing industries toward digitization, automation, and big data analytics will make this smart manufacturing revolutionary for designing, producing, and delivering products. Gone are the days when automation issues prevail, and the bigger deals are the use of advanced technologies such as AI, IoT, cloud computing, and robotics in every step of production. The power tool that businesses achieve through smart manufacturing would be making data-driven decisions on how best resources can be utilized with efficiency.

For electronics, chip design companies, circuit board design companies, and PCB design and manufacture, the smart manufacturing transformation is pertinent. These are extreme precision, high-speed production, and constant innovation—all of which can be greatly improved through smart manufacturing.

This blog will run through some basics on smart manufacturing, key technologies, a summary of the benefits, and how it can impact business operations for industries reliant on advanced electronics.

What Is Smart Manufacturing?

Smart manufacturing is simply a subset of Industry 4.0, and really, the digital transformations within the fourth industrial revolution. So, essentially, smart manufacturing revolves around creating advanced technologies in order to develop a highly responsive, agile, and efficient production system.

Smart manufacturing is the integration of all elements of production—from design to delivery—in an intelligent and automatized, interconnected framework that uses a combination of real-time data, machine learning, and interlinked devices to enhance the decision-making process, reduce waste, and refine operating efficiency. These include quality checks from robots and AI to integrating cloud-based platforms that improve supply chain management and communication in the value chain. Smart manufacturing really becomes an important tool for improving precision, speed, and quality control for most industries, such as electronics and PCB manufacturing.

Key Technologies in Smart Manufacturing

1. Artificial Intelligence (AI) and Machine Learning (ML): A game changer

Whether based on AI or ML, machines learn from data, adjust to the inputs received, and therefore improve over time. Old adjectives are being flipped upside down in the terminology as pertaining to traditional production processes to newer, smarter, and much more efficient and data-driven systems. These technologies enable machines, through large amounts of data, to learn patterns, make predictions, and adapt in real-time. This would thus allow for predictive failure of equipment in such a way that proper maintenance could be carried out before a breakdown has occurred, thus reducing downtime and ensuring higher productivity. For chip design companies, AI can bring improvements in real time within the design cycle by detecting the areas of inefficiency and suggesting improvements in real time. AI can work through vast data sets of previous designs to optimize future versions, eliminating errors and bringing faster time-to-market. Click here to understand about “How AI is changing the design process of semiconductors”.

2. Internet of Things (IoT)

IoT connects the physical world to the digital. That is, machines would now be able to ‘speak’ to one another; this is the crux of IoT. With IoT sensors put in machinery, performance as well as conditions may be monitored with real-time data sent to operators for better decision-making. In PCB design and manufacture, IoT may be applied in monitoring the process starting from the acquisition of raw materials, through production processes, and up to finished products. This ensures that quality control would not be deviated from while waste material is reduced and efficiency enhanced. Click here to get some interesting information on “How IoT is Paving the Way to a Greener Future”.

3. Digital Twin Technology

Digital twins are virtual replicas of the physical systems. Manufacturers can test, simulate, and analyze their production environments before switching over to them in the real world using these digital twins. This kind of technology allows for better design and testing of the systems as a result of fewer errors during the actual production stage and later costs.

Digital twin technology can be applied to circuit board design companies to validate and simulate their circuit layout and configuration in the virtual domain before the prototype is finalized. This allows circuit board design companies to test their designs for a significant reduction in time and cost.Here comes the picture in relation to digital twin technology used in manufacturing and circuit board design based on virtual duplicates of physical systems aimed at testing and optimization.

4. Big Data and Analytics

Data is the foundation of smart manufacturing. A manufacturer can collect, store, and analyze large amounts of data to make decisions about optimizing their process. Analytics with big data enable real-time monitoring, predictive maintenance, and demand forecasting.

Big Data analytics would be very helpful for chipping design companies in understanding performance issues, failure patterns, and so on, which help in improving product design. Data would help a company get the best production efficiency and thereby reduce the costs.

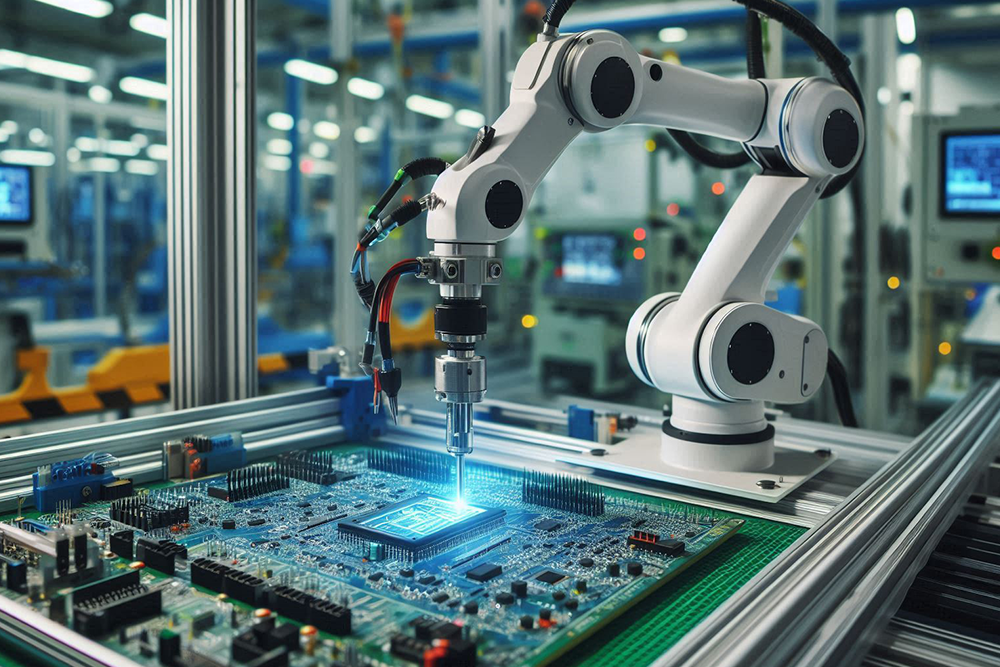

5. Robotics and Automation

The heart of smart manufacturing lies in automation. Such robots, with the aid of AI, can do complicated things in the shortest possible time, to an accuracy that is better than that of humans and without any risk of human error. Automated systems also take the loads off in assembly, testing, and packaging lines, hence giving higher value-added tasks to the human workers. This is possible for PCB manufacturing and design using automated assembly lines, which make fewer errors by the human elements and are faster in production. They can perform soldering and even assembling delicate parts using a vision system in order to ensure that the products are of good quality.

The Role of Smart Manufacturing in Electronics and PCB Design

The electronics industry just so happens to be the sector that is considered to be the most complex and fast-moving, thriving on continuous innovation. There are many advantages of such an organization with smart manufacturing—particularly those in chip design, circuit board design, and PCB design and manufacture.

1. Enhanced Design and Development

Smart manufacturing plays a game changer for the design phase with sophisticated technologies like advanced CAD software, simulation tools, and AI-driven design optimization. Industry leaders, such as chip design professionals, really appreciate the options that arise from the use of such tools:

- fewer possibilities of design errors

- reduced development cycles

The engineers will be able to perform:

- circuit performances using simulation tools

- recognize potential faults

- more chances to solve these faults even before the actual fabrication

Companies working on circuit design also employ these tools to:

- optimize circuits

- minimize physical prototypes

resulting in:

- reduced time-to-market

- product quality improved

- More competitiveness

Companies will be able to streamline design, reduce errors, and improve their rate of innovation through the integration of smart manufacturing technology into the world of electronics.

2. Enhanced Quality Control

Smart manufacturing ensures that there is flawless quality inspection of electronics, whereby minor flaws make products useless. AI-powered vision systems:

- Identify defects in real time.

- Predicts the trend of possible issues beforehand.

- Automate the inspection of PCB design and manufacturing: it ensures that every board will have passed all the set requirements and ensures minimal manual checks with higher overall product reliability.

Advantages:

- Fewer hands-on inspections

- Enhanced product quality

3. Increased Productivity

In oligopolistic markets with low margins, efficiency is the bottom line. Smart manufacturing makes production more efficient by:

- Removal of waste, less time is spent in the ‘downtime’

- Improved output

- IoT sensors for real-time monitoring and optimization of equipment

For companies of chip design or circuit board design, smart manufacturing:

- Eliminates manual settings or adjustments

- Automatizes a lot of processes with free release of human resources to innovation

4. Sustainability and Energy Efficiency

Smart manufacturing acts eco-friendly and reduces a majority of wastes and consumption of energy. Some of these points are;

- Predictive maintenance, which is part of the process that saves a lot while resources are being repaired

- IoT sensors optimize energy usage by automatically switching off idle equipment

- Data-intensive insights are at the heart of sustainably manufactured production processes

Outcomes:

- The waste generation is lowest.

- Energy input is decreased.

- The environmental sustainability in PCBs design and manufacturing is enhanced.

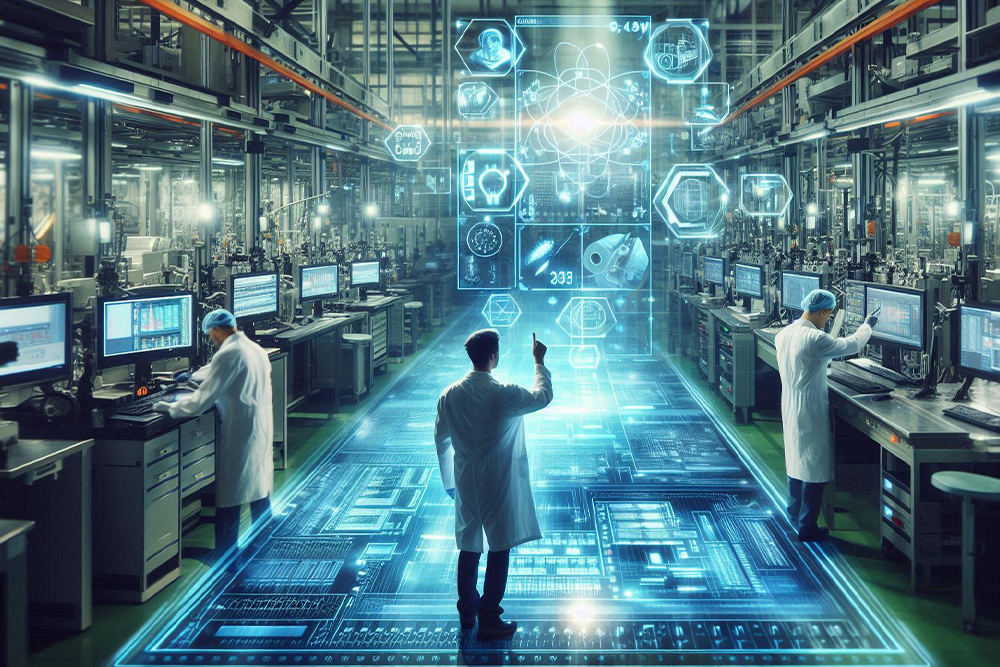

How Smart Manufacturing Transforms Operations: A Comprehensive Overview

Smart manufacturing is giving a new face to industrial operations, where advanced technologies like AI, IoT, machine learning, and robotics are integrated in all production and related processes. As such a modification changes companies’ internal structure, the companies can smartly optimize their efficiency, enhance product quality, and make data-driven decisions in real-time. Many industries of chip design, circuit board design, and production of PCB are quite interested in smart manufacturing, mainly because of its ability to effectively optimize operational performance and to change dynamically with the market. Smart manufacturing is transforming business operations—from supply chains to the shop floor. These new technologies offer the following major benefits:

1. Real-Time Data for Informed Decision-Making

Smart manufacturing provides real-time data to make informed decisions on efficiency, waste reduction, and optimum production. Companies with complicated supply chains or have several production locations need it. Click here to learn more about “How Emerging Technologies Can Drive Real-Time Efficiency in Semiconductor Manufacturing”. Chip designers and PCB manufacturers get these services:

- Detection of bottlenecks

- Optimization of equipment use

- Lead-time efficient production

2. Flexibility and Customization

Smart manufacturing breaks the rigidity of old-fashioned production so that the production can flex dynamically in terms of:

- Changing between product variants

- Scaling up or down

- Adding new products easily

Circuit board design businesses have the ability to efficiently handle:

- Low-volume, high-mix production runs

- Mass production

3. Reduced costs and increased profit margins

Smart manufacturing provides an opportunity to reduce costs effectively using process automation and waste minimization. Predictive maintenance minimizes downtime and repair costs, while AI design optimization reduces development cycles and time to market.

All of this serves PCB design and manufacture firms with lower unit costs, higher margins, and increased competitiveness in the marketplace.

The more extensive sharing of data increases collaboration among participants within the value chain.

4. Improved Collaboration Across the Value Chain

Smart manufacturing promotes connectivity and transparency across departments, with suppliers, and with customers. This means that the following ends are achieved:

- Improved quality of product

- Faster Time-to-Market

- Increased customer satisfaction

For a chip design company, this would mean working more closely with their suppliers to ascertain whether the materials precisely meet their specifications, and for a circuit board design company, they can enjoy close cooperation with their customers to give them timely updates about the production’s progress.

Conclusion

Smart manufacturing is no longer a future concept but a practical approach aimed at enhancing operational efficiency, product quality, and competitiveness. Smart manufacturing is more than just the latest buzzword for chip designers, circuit board designers and manufacturers. It is the only necessity for them.

Firms can reduce costs and increase flexibility and speed to market with the help of AI, IoT, automation, and big data. As technologies evolve further, the prospects for smart manufacturing will expand and provide the chance for much more innovation and excellence in operations.

The future belongs to intelligent manufacturing, and the firms embracing this transformation are going to be successful in this tough and complex global marketplace. Vendors, for more insightful blogs and case studies, visit us at Nanogenius Technologies.