The Impact of Generative AI on Transforming the Semiconductor Industry

A specialized branch of artificial intelligence is transforming the way various industries operate globally, and for the semiconductor industry as well called Generative AI. It can auto-design, process vast data volumes, and improve multiple operations. This makes it a strong tool for improving efficiency and driving innovation in semiconductor design.

As India competes for attention on the global semiconductor scene, generative AI might well be the catalyst that changes the game altogether. For example, by using this cutting-edge innovation, though, Indian semiconductor firms can improve their processes, come up with new products, and position themselves among the world’s leading semiconductor manufacturers.

This is not only which improve India’s place in the world but it will also attract investments and open new scopes.

An Overview of India’s Semiconductor Industry

This emerging power in semiconductor design and manufacturing has been supported by skilled engineers and friendly government policies in India. Many manufacturers in India, designing semiconductors, are adopting the latest cutting-edge technologies to compete against other giants in the world. “Semicon India Program” and semiconductor parks have stimulated innovation and investment.

Generative AI is poised to accelerate this momentum, aligning Indian companies closer to the global leadership in innovation and operational efficiency.

What is Generative AI?

Generative AI is the method used to create new artificial content or data that would be Images, Videos, Music, or even 3D models without any human effort. The development of Generative AI is derived from the advancements made in LLM (Large level language).

Generative AI models learn and train on datasets and design within the data, based on large datasets and patterns. They can then produce new examples similar to their training data. It allows these models to produce content without any human direction.

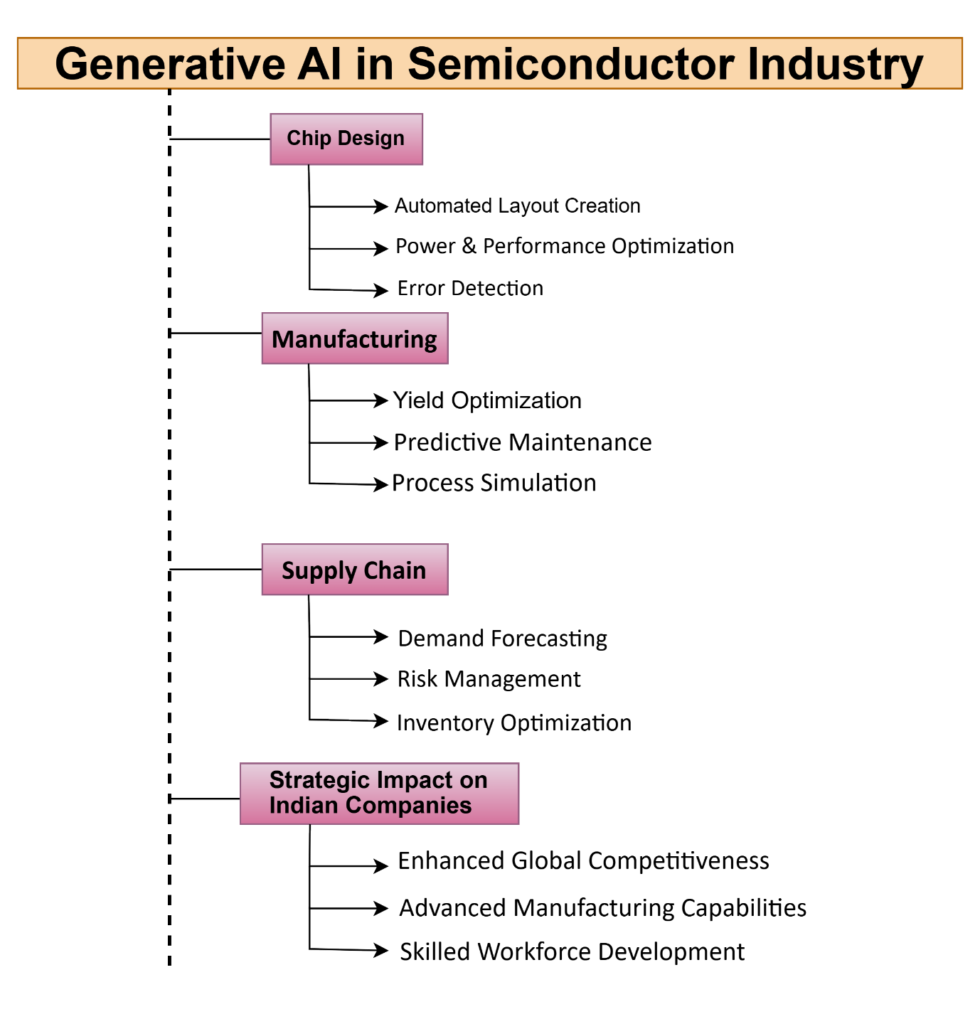

In simple words, it generally involves training AI models to understand various patterns and structures within existing data and using that to generate new original data. From simple tasks such as image generation and text generation to more intricate tasks such as design generation, generative AI is very effective in transforming the semiconductor industry. This can be achieved by offering solutions across multiple critical areas such as:

1. Manufacturing Process Optimization

In semiconductor manufacturing, precision and efficiency are key. Generative AI analyses production workflows to identify inefficiencies and suggests improvements. This leads to streamlined processes, higher productivity, and reduced waste, ensuring cost-effective operations.

2. Chip Design Automation

Generative AI simplifies and accelerates the process of chip design. This is because it automates the creation of layouts and optimizes designs for performance and efficiency, which reduces time and effort on manual design tasks. This makes chips more advanced and prepared for modern applications.

3. Supply Chain Management

Semiconductors’ supply chain is complex, with aspects that involve raw materials, inventory management, and logistics. Generative AI simplifies the process as

- Predicting Demand: by using algorithms that forecast market trends on the demand for chips so that manufacturers can produce accordingly.

- Optimizing inventory levels ensures that companies have just the right amount of stock—avoiding shortages or excess.

- Identifying the risks: The AI can identify where problems might lie in supply chain delays and shortages.

The application of generative AI across these spaces will lead to great strides in the semiconductor industry in innovations, efficiency, and reliability. It is a primary driver for the next transformation wave in the sector.

4. Predictive Maintenance of Equipment

Production machinery in semiconductor plants is highly sophisticated and needs to be maintained regularly. Generative AI models monitor the performance of this equipment, detect possible issues before they become failures, and recommend preventive action. This minimizes unplanned downtime and ensures continuous production.

Transforming Semiconductor Design

The Design phase is one of the most complex and crucial phases in the Semiconductor Manufacturing. It needs chips that are super-efficient, small, and cheap. This phase is undergoing transformative changes with the introduction of generative AI which allows automate and refine the design process. Here’s how:

1. Automating Design Creation

Designing a chip manually is very time-consuming and labor-intensive. Generative AI makes this task automatic by producing chip layouts quickly and with high accuracy. This automatically saves time and effort for engineers while maintaining consistent quality. For semiconductor designing manufacturers in India, this is particularly beneficial as it allows them to keep pace with the increasing demand and get products to the market sooner.

2. Optimizing Power and Performance

Chip performance is influenced by power consumption, heat management, and processing speed. Generative AI uses the most complex algorithms to determine these parameters and optimize them during the design phase. This means that the chips will work efficiently while using the least amount of energy, which is ideal for modern applications that require high efficiency.

3. Error Detection and Correction

During design phases, errors in chips often occur, leading to big financial losses when they have reached manufacturing. Generative AI models are perfect at showing probable design faults during initial development. In doing this, the technology saves errors and ensures the final output has met all standards expected.

Generative AI in Manufacturing

The impact of Generative AI on the semiconductor industry is not limited to the design of the chips. It also plays an important role on the shop floor. With AI-driven solutions integrated into production, processes become streamlined, efficient, and cost-effective to bring about great benefits for top semiconductor manufacturers in India. Here’s how generative AI is changing manufacturing:

1. Yield Optimization

One of the major challenges of semiconductor manufacturing is high wafer the percentage of usable chips from a wafer. Generative AI analyzes enormous manufacturing data to identify patterns and anomalies that can influence yield. Optimizing such processes helps AI reduce waste, improve profitability, and ensure consistent product quality.

2. Predictive Maintenance

Semiconductor manufacturing involves highly complex machinery that needs to be precise. Equipment failure can cause significant losses. Generative AI models track equipment performance in real-time, monitoring early warning signs of potential failures. Companies can schedule preventive maintenance and avoid unplanned outages, thus ensuring smooth operations.

3. Process Simulation

The manufacture of semiconductors is a multi-faceted activity that involves numerous process steps. Generative artificial intelligence offers models of such processes in a virtual environment, allowing the manufacturing side to see the workflow processes, define the problems, and validate the modifications in real-time without interrupting the manufacturing process. Such simulations render useful information that helps manufacturers to make improvements in the processes and be more effective.

Click here to learn about the fundamentals of AI chip architecture in this comprehensive guide.

In this situation generative AI allows Indian semiconductor manufacturers to improve their production efficiency, cut back on costs, and increase their competitiveness in the global semiconductor market.

Impact on the Semiconductor Supply Chain

India is in the midst of a transformative semiconductor industry, and generative AI has been offering tremendous potential to further innovation and place the country on the global map. By adopting generative AI, Indian companies would be able to achieve significant breakthroughs in several critical areas.

1. Chip Design Services

Generative AI revolutionizes chip design in India. It automates difficult tasks, and optimizes performance and error-free production, helping Indian companies to be in prime position as a major service provider of advanced design solutions for international semiconductor giants. Such improvements will not only promote visibility but also guarantee trust in being a reliable partner with innovative ideas in the global semiconductor ecosystem.

2. AI-driven manufacturing hubs

These lines can transform traditional manufacturing operations into highly efficient and most current technologies. AI in Indian lines will improve productivity, higher yields of wafers, and reduce waste. Such centers for AI-based manufacturing systems will make India comparable with global leaders and be considered the world’s top companies within this semiconductor industry, with significantly good growth in the country.

3. Skilled workforce development

Generative AI adoption will need a workforce skilled in both AI technologies and semiconductor design. Indian organizations can invest into upskilling courses and collaborations with educational institutions to foster a talent pool of meticulous engineers. Such emphasis on skill-building will not only allow the industries to thrive but also innovate at a breakneck pace that technology requires.

Challenges in Adopting Generative AI

Its adoption brings along various difficult barriers in promising much for the semiconductor industry. Some of the challenges that companies must cross to take full advantage of it are listed below:

1. High Computational Costs

Training generative AI models are very resource-intensive, requiring significant computational powers; most companies resort to very expensive hardware like GPUs or TPUs. Most firms, especially smaller ones, cannot afford this cost. Almost as important is the question of balancing the commitment made to the resource-intensive investment against the hoped-for benefits resulting from the inclusion of AI capabilities.

2. Data Security Concerns

The semiconductor industry is basically driven by very sensitive and proprietary data related to design and the manufacturing process, with all the supply chain information. Data breaches or leakages are a grave concern with AI in the workflow. Thus, proper security measures need to be integrated while using generative AI to maintain data integrity, focussing on this crucial issue.

3. Skills Gap

It is therefore a talent gap requiring interdisciplinary skills in AI and semiconductor technology. For now, however, it impedes the companies scaling up AI fast by slowing down the rollout of AI solutions. It takes interactions with academic and technical bodies and targeted training programs for this gap to be bridged.

Overcoming all these challenges will be required for companies that want to include generative AI in their business. AI is powerful and will mark great strides in the semiconductor industry when all these barriers are overcome.

Flow Chart: Role of Generative AI in Semiconductor Industry

For a deeper understanding of how AI is reshaping chip design, check out this insightful article: “Chip Design Innovations for the Age of AI and Machine Learning“.

Conclusion

With the advent of generative AI in the semiconductor industry, tremendous scope can be tapped for changing design, manufacturing, and supply chain management. This technology has been an opener to help the designing semiconductor companies in India to lead globally. In case this country continues its pace of innovation and investment, India can house some of the best companies in the world related to semiconductors. Thus, Generative AI is not a supplement but a pillar that forms the base of its next evolution in the industry. Discover more about this and other ground-breaking innovations, and stay updated on the latest industry trends with Nanogenius Technologies.