Role of AI-Enabled EDA Solutions in Shaping Semiconductor Systems

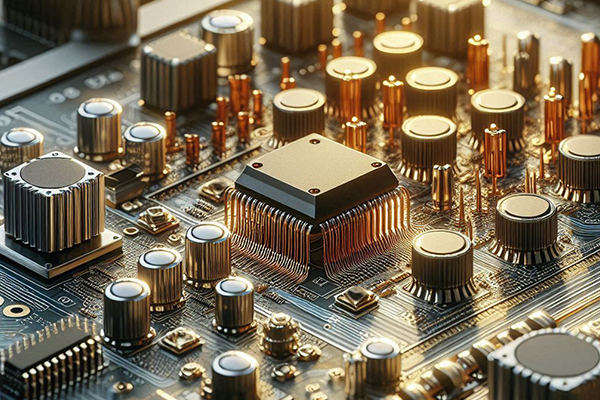

The semiconductor industry has always been at the frontline regarding technological advancement. Chip and circuit design is becoming even more agile with rapid advancements in Electronic Design Automation (EDA). Artificial Intelligence (AI)with the toolsets powering EDA is starting to create a paradigm shift in how semiconductors are designed and fabricated.

In the following, we will discuss how AI is going to revolutionize EDA, define which path semiconductor technologies of the future take, and overcome some of the most serious challenges across the industry.

What is Electronic Design Automation?

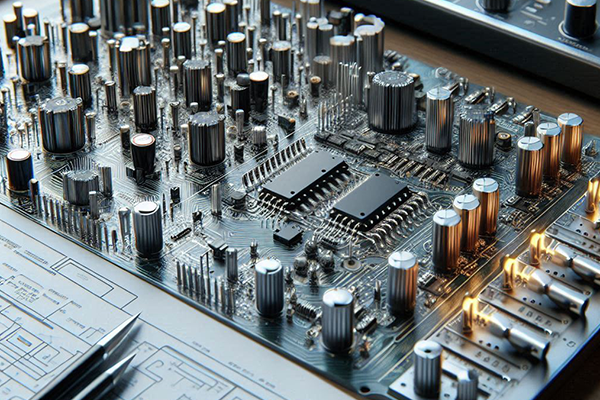

EDA software tools enable a designer-engineer to design, verify, and simulate an electronic circuit and system. These automated technologies complete various design activities that otherwise would have taken longer and been more prone to human error. For the semiconductor manufacturing sector, where accuracy is crucial, EDA designs printed circuit boards, integrated circuits (ICs), and other electronic systems.

Curious about how this tool works? Check out this beginner’s overview of EDA tooling.

How AI is Changing the Game for EDA

In recent times, Artificial Intelligence has been a game-changing factor in EDA. In utilizing complex machine learning algorithms and data analytics, AI-driven solutions to EDA can predict when design bottlenecks will happen, streamline the workflow, and keep the margin of error at a minimum. This is achieved via:

AI Rule Checking

Traditional DRC is extremely time-consuming. Automation runs for the process by AI-driven EDA tools, and the probable issues are flagging automatically against the pre-set parameters hence saving lots of time and reducing the number of costly revisions to the barest minimum.

Want to know more about AI-driven DRC?

Simulation Accuracy

AI further enables the power of simulation by its deep learning from previous design data. Such simulations allow the engineers to predict circuit performance more accurately and hence can find the bottlenecks quite early on in the design cycle.

Curious how AI optimizes simulations? Take a deeper dive into AI in the simulations.

Layout Optimization:

The physical placement of components is a crucial task in any semiconductor design.

AI-driven layout optimization offers better performance with less power and space; hence, higher-performance chips in a smaller footprint are achievable.

Role of AI in Semiconductor Manufacturing

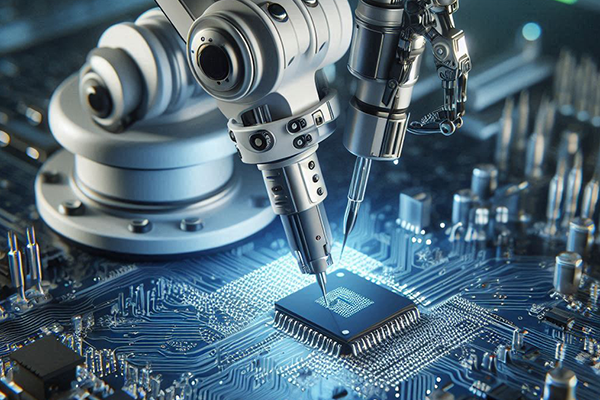

Not only does AI improve semiconductor design processes, but it also optimizes semiconductor manufacturing processes. Let us probe a little deeper into its contribution:

Process Variability Control:

Semiconductor manufacturing involves hundreds of variables that constitute yield and performance. AI observes this production data in real-time, looking at trends and delivering actionable insights toward consistency and further efficiency.

Yield Prediction: One of the most vital successes of AI can be seen in yield prediction-that is, the percentage of chips coming out functional. In so doing, this enables manufacturers to minimize waste and increase productivity by relating design choices to production data.

Supply Chain Logistics:

Currently, AI is transforming supply chains by optimizing inventories and forecasting market demands. AI-driven supply chain management shall also enable semiconductor firms to manage resources better and improve reliability.

Challenges of AI-Driven EDA

Though AI offers a lot of benefits, yet challenges that need to be considered include:

Data Privacy & Security:

AI operates only on Big Data, and that, in turn, puts a lot of emphasis on data privacy. Semiconductor companies may have sensitive IP, and they want that protected at all costs. Interested in learning more? Delve deeper into the world of ore? Explore data privacy concerns in AI.

Complexity of AI Models:

Training and maintaining AI models can be complicated and, hence, beyond the comfort zones of certain companies. For companies new to AI, steep learning curves in adopting these tools may exist. Want to know how companies overcome such challenges? Here’s how companies are managing AI adoption.

Integration with Legacy Systems:

However, most semiconductor companies still operate on legacy systems that may not support these newer AI-driven EDA tools. Their migration to modern solutions takes effort and time. Read how companies upgrade their legacy systems.

Future Trends in AI-Driven EDA

In the future, AI will continue to show the path to new exciting futures for semiconductor technologies:

Machine Learning Advances:

Shortly, deep learning and neural networks will make EDA tools much smarter and faster. This on the one hand will let the designers do design simulations that are orders of magnitude more complex, and on the other hand, new design rule checking and layout optimizations will be enabled. Curious about what else is coming up next? Have a look at the future trends in deep learning.

Collaborative Platforms:

This will include the use of AI for collaborative EDA platforms where engineers collaborate in real-time on work, sharing data and insights. It’s revolutionary how design teams collaborate today and drive innovation.

Quantum Computing Integration:

Quantum Computing-unlocking new possibilities in semiconductor design. Having both AI and quantum computing in one place enables engineers to overcome those design hurdles hitherto deemed insurmountable. Interested in learning how quantum computing may change EDA? Explore the future of quantum computing in semiconductors.

Conclusion: Semiconductors’ AI-Driven Future

It has only just begun to revolutionize the semiconductor industry in several areas, including supply chain optimization, increasing the capacity of manufacturing, and efficiencies in design. The future of AI in EDA is surely bright, though there are obstacles that must be addressed and overcome.

Any idea what the future of semiconductors will be? Stay updated with all the latest developments in AI-driven innovation. Join the revolution now and access more information at Nanogenius Technologies.