ASIC Design Flow – The Complete Guide to VLSI Blueprint

In electronics, custom semiconductor solutions are fast becoming a prerequisite. From smartphones to aerospace technology, the heartbeat of most high-performance systems lies in Application Specific Integrated Circuits (ASICs). ASIC design flow is becoming the way out for businesses that seek performance at a lower cost.

This guide will walk you through, step by step, how the ASIC design process is done from concept to silicon during its different phases. Be it for a consultation on ASIC design, custom ASIC solutions, or even working with a PCB design company, this blueprint will surely help take the mystery out of ASIC development.

An Application-Specific Integrated Circuit, or ASIC, is a chip that is built to perform a specific function or application, whereas general-purpose ICs are as found in any CPU or GPU. ASICs are more optimized toward their target application because of the high gain they provide on power consumption, performance, and size.

Because ASICs are designed from the ground up for a special purpose, they can be more efficient than general-purpose chips. For example, a custom ASIC design for a smartphone would probably work on signal processing, encryption, and image rendering much more efficiently than the general-purpose chip.

If you want to dig deeper into the basics of ASICs, read this comprehensive overview.

The ASIC Design Flow: A Step-by-Step Blueprint

The ASIC design flow is the sequence of processes that takes an initial idea from concept to a physical chip. These include multiple stages, which are each crucial in leading to the final product. Some important phases in ASIC design are:

- Specification and Conceptualization: Specification All ASIC designs begin with a specification phase. This process is critical because it defines what the ASIC will do, how fast it will operate, how much power it will consume, and its physical size. Well-defined specifications are the basis of any successful ASIC.

Specification phase Usually involves

- Functional Requirements specify: what the ASIC should do

- Performance Targets: Power, speed and area constraints

- Considerations of Environment: Will the chip need to operate in hostile environments, or does it require special thermal management?

Consulting with a professional ASIC design consultation team at this point ensures that your specifications will fit the business objectives. Want to know what perfect specifications should be? More here.

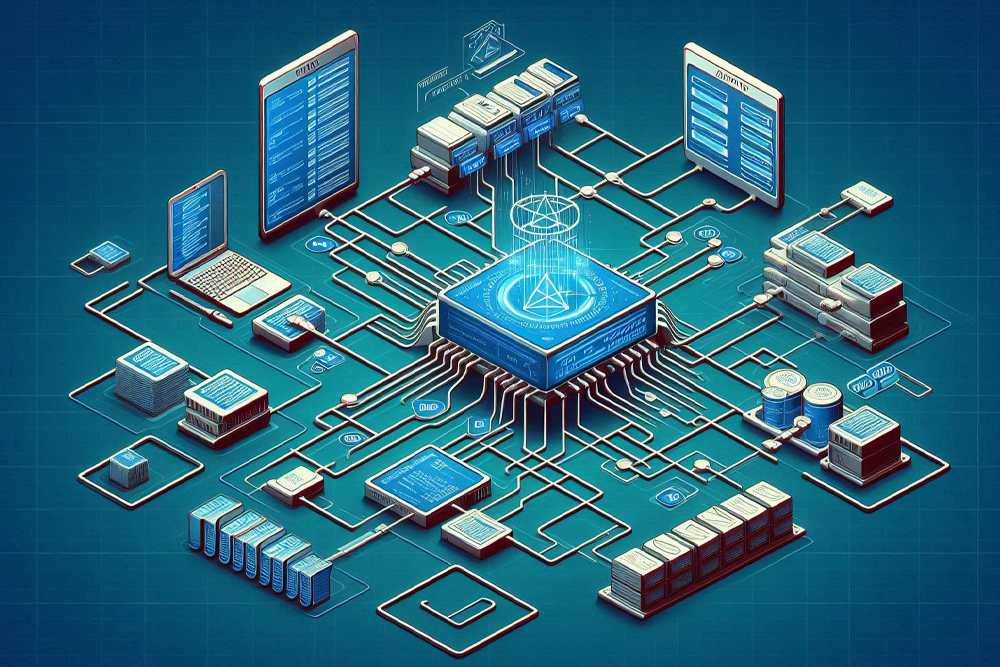

- Architecture Design: Once the specifications are defined, design the architecture of the ASIC. In this step, important building blocks such as data paths, control units, and memory elements are outlined. Architectural design decisions are significant because they dictate the overall performance, power consumption, and chip area.

- Data flow modeling: It is modeling how the data is going to flow through the system.

- Control logic: Determining how the different blocks in the ASIC will interact

- Power and performance: Creating a design that meets power budgets for the level of performance

To learn more about ASIC architecture design, click here.

- RTL Design (Register Transfer Level): This interpretation stage comes at the Register Transfer Level or RTL. The RTL code can be written in hardware description languages like Verilog or VHDL. This precisely specifies how data flows through a given system, including what logical operation the system is performing.

Designing RTL is essential since it is the basis of what ultimately forms the chip to have its working. An efficiently optimized RTL design makes it highly crucial for the betterment of final ASIC efficiency and performance.

Do not know where to start working with RTL? Get an experienced PCB design company that specializes in RTL designs for ASICs. Know more here.

- Design Verification: Verification is a process to ensure that the RTL design embodies the specifications. This stage of design testing makes use of many simulation and formal verification techniques applied to bugs, logic errors, and corner cases. The cheaper design bugs are likely to be the earlier you detect them.

Amongst the techniques applied are:

- Simulation: Run the RTL code in a simulated environment and see how it behaves.

- Formal Verification: Proving mathematically that the design performs exactly as you anticipate.

- Functional Verification: Verify whether the design meets the functional requirements as specified.

Want to learn more about advanced verification techniques? Click here to take a closer view.

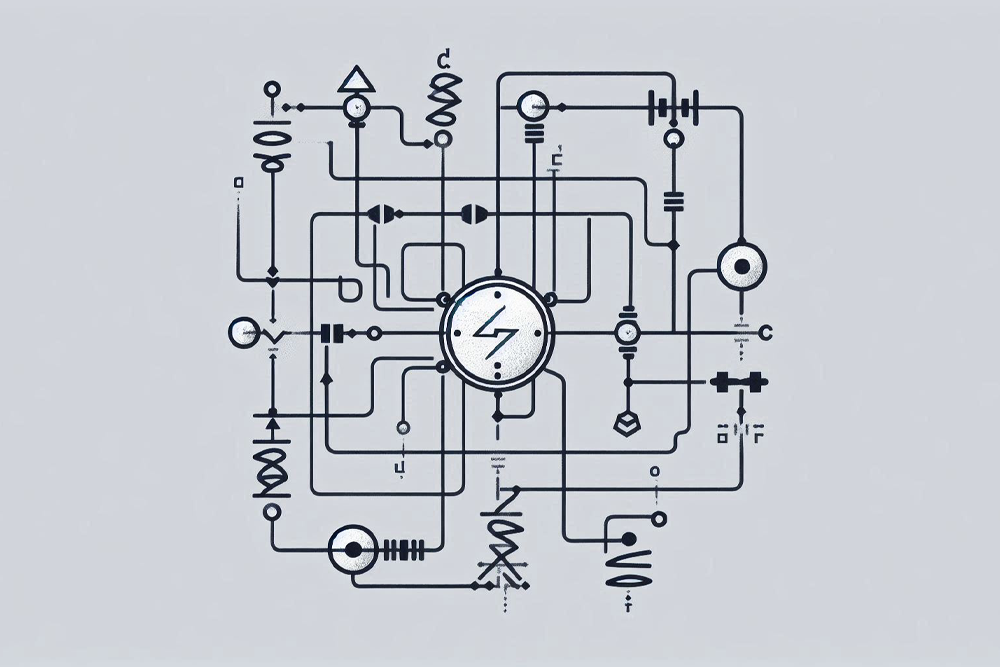

- Synthesis: Once the RTL is verified, the synthesis step is taken. This step translates the high-level RTL code into a gate-level netlist. Precisely, synthesis translates your design to a form that uses real logic gates from your target technology library.

- Mapping RTL to gates: Given the technology libraries translate RTL into a gate-level design.

- Optimization: This reduces power, area, and timing to meet performance goals.

- Technology-specific mapping: Map input netlists in a way optimized for fabrication.

Curious about how synthesis tools can aid your design? Take a look at this synthesis guide – including what role synthesis plays in ASIC development.

- Place and Route (P&R): The place and route phase is where the gate-level netlist is used in order to position the components on the silicon chip. It determines such factors as final ASIC size, power consumption and performance, so this is really quite crucial.

- Placement: Determines where each logic gate will go on the chip.

- Routing: Creates all the connections between gates so that data can flow correctly.

- Power and Clock Planning: Ensure the chip can meet its power needs and stay in sync.

A great P&R strategy will greatly enhance a chip’s performance. Learn more about best practices in physical design and more in best practices reading.

- Timing Analysis: Static timing analysis is used to check whether the design satisfies the required timing constraints. Timing analysis ensures signals will propagate in the chip within the specified number of clock cycles, thereby avoiding problems such as setup and hold violations.

Key concepts in timing analysis:

- Clock tree synthesis: The spreading of the clock signal throughout the chip.

- Timing closure: It guarantees all paths in the design meet their timing requirement.

One of the most critical aspects in designing ASICs is the timing, and then there is this proper link if you are interested in diving deeper into the analysis techniques of the time.

- Physical Verification: Physical verification is also necessary before entering into fabrication so that the manufacturability of your design is ensured, and checking includes:

- Design Rule Check (DRC): This ensures that the rules for the given manufacturing process are followed.

- Layout vs. Schematic (LVS): This ensures the similarity of the actual original design with the physical layout.

- Electromigration (EM) Analysis: Searching for potential wear on metal lines due to high currents.

Physical verification is also an essential check for catching errors that can result in costly silicon re-spins. Learn more here about physical verification techniques.

- Tape-Out: This is the final step where a design will be formally handed over to the fabrication foundry for actual fabrication. In this phase, all mask sets that are necessary for actual production will be created, and the design will become frozen.

Tape-out is a significant ASIC design flow; it is that point in time when the design moves from the design to the manufacturing phase.

Ever wondered what tape-out is and what’s next? Read on how to prepare for tape-out.

- Fabrication: The design here is translated into silicon wafers via fabrication. Fabrication can be defined as involving several difficult steps including:

- Deposition: Deposition refers to the laying of layers of material on the wafer.

- Photolithography: Exposing layers to light to transfer patterns on them.

- Etching: Removing material to define the final structures on the chip.

ASIC fabrication is typically outsourced to foundries. However, keeping the stake and control at this stage is important for quality. Curious about how to choose a foundry? Find out what to consider when selecting a manufacturing partner.

- Testing and Verification: After fabrication, the first batch of chips are tested and validated to ensure that they conform to specifications established before. The three types of testing include:

- Functional Testing: Testing to confirm that the chip performed as intended

- Parametric Testing: Testing to determine the electrical characteristics such as power consumption and signal integrity.

- Environmental Testing: Stressing the chip under various environmental conditions including extreme temperatures and voltage.

Testing is one of the most important implementation phases aimed at determining whether the ASIC will thrive in its final product. Click here for information on ASIC testing processes.

- Packaging and Deployment: The final step in the ASIC design flow is chip packaging for deployment. Packaging is needed to protect the silicon die and provide electrical interconnection to the larger system. The appropriate package depends on the thermal, mechanical, and electrical requirements of the application.

Packaging alternatives include:

- Wire bonding: The silicon die is connected to the package by the use of fine wires.

- Flip-chip: Mount the silicon die upside down and contact it directly to the package substrate.

Once packaged, the ASIC is ready for final product integration. Curious about how packaging affects chip performance? Learn more here.

Custom ASIC is the best solution that further leads to the optimization of power, performance, and cost for a specific application for a company. Custom ASICs have several advantages, among them include:

- Efficiency: Dedicated to a particular application; hence lower power.

- Performance: Designed for speed and high throughput.

- Economical: Development is expensive, but ASICs can be an economical proposition in high-volume manufacturing.

Considering adding custom ASIC solutions to your business? See the advantages here.

ASIC Integration with a PCB Design Company

The selection of the right PCB design company is critical in ensuring successful ASIC integration into the system. The PCB layout and design contribute greatly to signal integrity, power distribution, and general performance.

A good PCB design company should offer the following:

- Optimize signal paths: It will ensure high-speed data transmission.

- Improve thermal management: It will ensure that the board dissipates heat efficiently.

- Compatibility: It will ensure integration with other components of the system.

See For the best PCB design companies, read more about what you should look for in a PCB design firm.

Final Thoughts: The ASIC Design Path

Every ASIC design is a journey from a concept to silicon. It could be long and sometimes challenging. But before that is knowledge of how to walk the aisle successfully with ASIC design flow. Be you are working as an ASIC design consultation expert, creating a custom ASIC or hiring a PCB design company, a clear roadmap is important.

Want to know about ASIC design? Check out more articles and insights at Nano Genius Technologies.

- What is an ASIC vs FPGA?

ASICs are manufactured-to-suit applications. As opposed to this, FPGAs are Programmable/Gates Arrays: programmable and flexible; hence ideal for prototyping or applications requiring frequent updates; though they tend to be much more power-efficient and suited for mass production. Learn more.

- How long does it take to design and manufacture an ASIC?

ASIC design time: the level of complexity of the design determines the minimum period that would be allocated to the development process for the design. It can take a few months to over a year. Following the design, several months are usually taken for fabrication and testing. Read more on design timelines.

- How do I select the right PCB design firm for ASIC integration?

When you choose a PCB design company for your business, you must choose one that specializes in high-performance designs or is compatible with custom ASICs and that can provide a rich track record in similar applications. Check out this guide for tips on choosing the right partner.