Adapting to Change – Exploring the Challenges and Opportunities in Semiconductor Manufacturing for the Next Decade

Introduction

The semiconductor chip production process has played an accelerator role in technology innovation within consumer electronics, telecommunication, automobile, and the defence industries. Such requirements in life being digitized are becoming increasingly energetic and power-intensive, which continue to pose the demand for such innovations. The decade holds huge challenges and opportunities for adaptation toward increasingly changing technology shifts, global supply chains, environmental concerns, and a change in the nature of market requirements.

This case study deals with the risks and opportunities that the semiconductor manufacturing industry will pose in the next decade. To this effect, we dealt with major technological innovations, key supply chain vulnerabilities, concerns related to sustainability, and how a change in geopolitics will affect the sector. We shall examine the kinds of strategies that companies can undertake to stay ahead of and leverage changes and opportunities for sustainable growth.

I. The Current Landscape of Semiconductor Manufacturing

1. The semiconductors industry Today

The semiconductor industry is the unseen hero of our modern world. Supporting cutting-edge tech like AI, IoT, and self-driving cars, its impact will only continue to expand, reaching a staggering $600 billion value by 2025. This rate of digital transformation within such a broad scope of industries merely fuels demand for semiconductors to nearly insatiable levels.

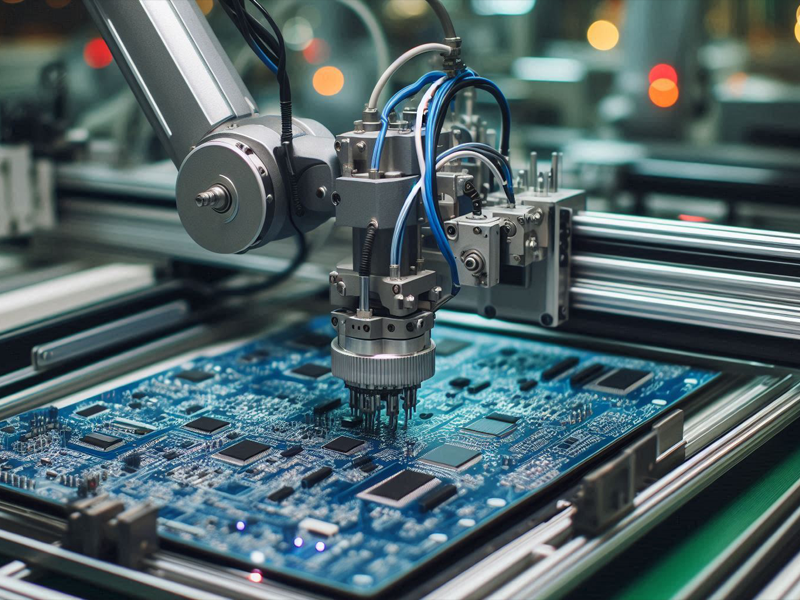

Nowadays, Taiwan Semiconductor Manufacturing Company, Intel, and Samsung are the industry leaders in semiconductor manufacturing. It has a very unique world supply chain, whereas every step in production often falls on several locations—from design to fabrication, packaging, and testing.

2. Evolution of Technology Nodes

Such is the case in the semiconductor industry: moving at a pace largely unplanned, where the drivers are largely adherent to Moore’s Law, which foretold that transistors on a microchip would double almost every two years, Mottonen noted. Today, manufacturers are already putting into production chips with 5-nm nodes, and they are actively researching even smaller nodes—3nm and even 2nm. However, as the transistors reach the atomic scale, the process becomes progressively difficult and costly to operate. Therefore, scaling technology nodes becomes difficult in attempts to lower cost inefficiencies and performance gains. Companies will have to seek alternative approaches toward semiconductor performance advancement in the next decade.

II. Challenges Facing Semiconductor Manufacturing in the Next Decade

1. Supply chain and geopolitical risk

One of the biggest challenges for the semiconductor industry, perhaps, is that it operates on a supply chain that is extremely globalized. Some vulnerabilities were exposed by the COVID-19 pandemic, and it led to a global chip shortage, not halting and beginning to disrupt many industries—from automobiles to consumer electronics.

Extremely concentrated semiconductor fabrication within a few regional hotspots, such as Taiwan or South Korea, would pose extreme concerns over the vulnerability of the industry to geopolitical tensions and natural disasters. Indeed, Taiwan is an important node in the global supply chain and produced more than 60% of all the world’s semiconductors. A hiccup in this region—be it political conflict or environmental catastrophes—would send shockwaves across the globe in technology markets.

Major risks:

- Trade tensions are growing between the U.S. and China, which may impose export controls on critical semiconductor technologies and materials.

- Its upsurge of nationalism and protectionism may imply an impetus to countries to place export restrictions or encourage homegrown chip production, thus achieving self-sufficiency.

- Cybersecurity risks, especially as all semiconductor manufacturing processes become increasingly digitalized and automated.

2. Technological Complexity and Cost

As semiconductor technology advances beyond the 5 nm node, development and manufacturing become a costly affair. Each successive node entails enormous capital input into research, special equipment, and advanced manufacturing techniques. The requirement for extreme ultraviolet (EUV) lithography, for example, is not only a costly innovation but also one that is necessary to create tiny transistors in chips.

With growing shrinkage of size in chips, manufacturing processes grow complex; errors are given less margin. The problems manufacturers have to suffer are:

- Yield management in which small defects render chips unusable.

- Heat dissipation as well as power efficiency. This varies from high-end applications, AI, and 5G that require high-performance chips.

- Material limitations, in that silicon-based chips are reaching the physical limit, are thus a reason for new alternatives such as gallium nitride (GaN) and silicon carbide (SiC).

3. Talent shortage

The most critical areas of engineering, design, and manufacturing have a gargantuan talent gap—unlike any other industry. And this gap is only growing as more demand for specifically developed skills in AI, quantum computing, and others such as advanced material science, among others. These companies are so desperate to hire experts in semiconductor know-how as it is acquired by technology, automotive, and other firms working within defence.

The semiconductors need to train their workforce as part of development in order to overcome the challenge:

- The company supports and works hand-in-hand with universities and other research institutions in developing future engineers and scientists.

- So, attract the best people from across the world with competitive compensation packages. Diversity and inclusion would encourage the harnessing of the hidden reservoir.

III. Opportunities for Growth and Innovation

1. Emerging Technologies: AI, Quantum computing, and 5G

One of the biggest opportunities for the semiconductor industry is that there are new technologies that require more and more powerful chips.

Artificial Intelligence (AI): With the vast application in fields from healthcare to finance, the same actually augments the need for specialized chips which can handle massive processing of data and machine learning. As a result, there is a huge requirement for AI accelerators such as graphics processing units or GPUs and application-specific integrated circuits or ASICs.

Quantum Computing: The early phase of quantum computing is still in the early stages, but already it may be the future of many industry transformations by solving complex problems that exceed what any current classical computer can do. Semiconductor companies are beginning to invest in developing quantum chips that operate with different principles than traditional transistors.

5G and Beyond: The rollouts of 5G networks are pushing the demand for high-performance chips for better data transfer with less latency and elevated connectivity. Perhaps we will live in a world of 6G ten years from now; at least, innovation and design fabrication of semiconductors might have gone further.

To get more knowledge about “How Emerging Technologies Can Drive Real-Time Efficiency in Semiconductor Manufacturing,” click on the given link.

2. Decarbonization and Sustainability

Sustainability is quickly becoming an important issue in the semiconductor industry, since companies and governments are realizing that things need to change, reduce their carbon footprint, and consume less of the planet.

Silicon manufacturing is very energy-intensive and contributes to a really large carbon footprint in the manufacturing of chips, tied to chemicals, water, and power consumption. The pressure on manufacturers to move towards sustainability will only increase in the following decade, among others:

- Using less energy by producing more efficiently.

- Material recycling and reduction of waste in chip fabrication.

- Formulation of environmentally friendly alternatives to dangerous chemicals in production.

This would mean the possibility of recycling old chips and making new materials with the circular economy initiatives. In general, other global sustainability goals, like reducing greenhouse gas emissions through what the Paris Agreement says in relation to limiting the increase in global warming, would be compulsory for semiconductor companies.

3. Regionalization of supply chains

Hence, the geopolitical risk and vulnerability associated with the supply chain create an ever-increasing necessity to geographically diversify semiconductor manufacturing away from single markets. Governments in the U.S. and Europe are developing incentives that encourage chip production onshore and reduce their dependence on offshore suppliers.

For example, the U.S. CHIPS Act is going to further augment the arsenal of semiconductor manufacturing capabilities through incentives toward building new fabs back on American soil. The European Union launches a European Chips Act with a goal to increase the share of the region in chip production worldwide.

Such programs will enable chipmakers to expand, build new plants, and enjoy access to more diversified supply chains. Business will need to balance regional diversification advantage against cost and complexities of exploiting scalable production in several sites.

IV. Strategies for Success in the Semiconductor Industry

In the next decade, semiconductor companies will need to be forward-looking strategists to continue through ups and downs. Some of those strategies will be:

1. R&D and Innovation Investment

The leading semiconductor firms would need to invest in R & D constantly to be able to compete effectively. Firms would have to develop novel technologies such as AI, quantum computing, and 6G, new material utilization, and new manufacturing methods. Co-operative partnerships involving universities, research institutions, and technology firms encourage innovation and breakthroughs in chip design and production.

2. Building Resilient Supply Chains

It will help companies avoid such risks in the future by diversifying their supplier base and acquiring multiple regional production capabilities. At the same time, digital tools for managing their supply chains will enable companies to strengthen their visibility and agility in supporting better responsiveness to disruptions.

3. Develop Your Talents:

Talent development should be an end in itself; so, semiconductor companies should invest in all available education and training, build close partnerships with academic institutions, and create inclusive work environments to attract diverse talent.

4. Embracing Sustainability:

The higher degree of sustainability—less in the use of energy in semiconductor manufacturing and embracing circular economy—must be imbedded across all aspects of this industry. Commitment to sustainability proactively creates space for applicable regulations, and competitive advantages in comparison with consumer and investor expectations.

Conclusion

The next decade promises deep transformations for the semiconductor manufacturing industry but, in them, an unprecedented chance for growth and innovation. Big challenges—big vulnerabilities in the supply chain, increasing factors of cost, technological complexity—and the opportunities come along with all these. Emerging technologies, talent development, sustainable practices, and diversified supply chains can take semiconductor companies onto the trajectory of change and prosperity in a world whose digital and connected nature is yet more intensifying.

And so, the best-positioned candidates to lead the industry forward would be the ones who emphasize adaptation, innovation, and sustainability in the new landscape.

Visit Nanogenius Technologies for an extensive library of blogs and case studies.