How AI is Transforming Semiconductor

Design Processes

The semiconductor industry is the backbone of modern technology, driving innovation across various sectors, including consumer electronics, automotive, healthcare, and telecommunications. As the demand for smaller, more efficient, and powerful chips grows, semiconductor companies are turning to Artificial Intelligence (AI) to revolutionize their design and manufacturing processes. AI is transforming the semiconductor industry by enhancing design accuracy, reducing time to market, optimizing chip performance, and cutting down costs. This blog explores how AI is reshaping semiconductor design, with insights into the role of top semiconductor companies, chip manufacturing companies, and chip design companies.

The Role of AI in Semiconductor Design

Semiconductor design involves complex processes such as circuit design, simulation, verification, and physical implementation. These stages are intricate and often require significant computational resources and time. AI, with its ability to learn from data, identify patterns, and make predictions, is transforming these traditional design processes.

AI-Driven Design Automation

One of the most significant contributions of AI in semiconductor design is the automation of Electronic Design Automation (EDA) tools. AI algorithms are now integrated into EDA software, helping in tasks such as schematic generation, layout optimization, and timing analysis. For instance, top semiconductor companies like Intel and NVIDIA leverage AI- driven EDA tools to reduce the design cycle time and improve chip performance. AI’s ability to analyse massive datasets enables these tools to make design decisions that were previously human-intensive, reducing errors and enhancing efficiency.

Enhancing Functional Verification

Functional verification is a critical step in semiconductor design, ensuring that the chip functions as intended. This process can take up to 70% of the overall design time. AI, particularly machine learning models, is transforming verification by predicting potential design errors early in the development cycle. Chip design companies like Cadence and Synopsys are using AI-driven verification tools that learn from past designs to predict and prevent failures, significantly speeding up the verification process.

Optimizing Chip Layout and Placement

The layout and placement of components on a semiconductor chip are crucial for performance and power efficiency. AI algorithms, particularly reinforcement learning, are used to optimize these layouts by exploring numerous configurations and identifying the most efficient design. Google, in collaboration with top semiconductor companies, has developed AI tools that outperform human designers in placement optimization, reducing the time required from weeks to hours.

Predictive Maintenance in Chip Manufacturing

In chip manufacturing, predictive maintenance driven by AI helps in identifying equipment failures before they occur, thereby reducing downtime and increasing yield. Chip manufacturing companies like TSMC and Samsung employ AI algorithms to monitor the health of their machinery, predict malfunctions, and schedule maintenance at optimal times. This not only saves costs but also ensures consistent production quality.

AI in Chip Manufacturing Processes

While AI’s impact on design is profound, its role in chip manufacturing is equally transformative. From material selection to wafer inspection, AI technologies are streamlining manufacturing processes, improving efficiency, and reducing defects.

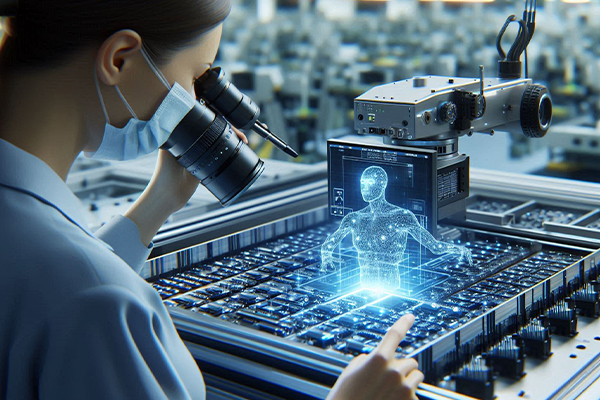

Defect Detection and Quality Control

AI-powered visual inspection systems are now a staple in semiconductor fabrication plants.

These systems use machine learning algorithms to detect defects on wafers that are often invisible to the human eye. Chip manufacturing companies like Global Foundries and Micron use AI-driven inspection tools to improve the quality control process, ensuring that only defect-free chips make it to the market.

Yield Optimization

Yield optimization is a critical factor in semiconductor manufacturing, as it directly impacts the profitability of chip manufacturing companies. AI helps in analysing production data to identify patterns and variables that influence yield rates. By adjusting these variables in real time, AI ensures optimal production conditions, reducing waste and increasing output. Top semiconductor companies are increasingly investing in AI-driven yield optimization tools to stay competitive.

Supply Chain and Inventory Management

The semiconductor industry faces complex supply chain challenges, including fluctuating demand, component shortages, and logistic constraints. AI is transforming supply chain management for chip design companies by predicting demand trends, optimizing inventory levels, and enhancing logistics. AI-driven supply chain solutions help semiconductor companies minimize delays and ensure a steady flow of materials, which is critical in meeting the global demand for chips.

AI in Action

Intel: AI-Powered Design Optimization

Intel, one of the top semiconductor companies, has embraced AI to enhance its design processes. The company uses AI-driven tools to optimize circuit design, reduce power consumption, and improve performance. By leveraging machine learning algorithms, Intel has reduced the time required for design iterations, accelerating time to market for its latest chips.

NVIDIA: AI in GPU Design

NVIDIA, a leader in GPU technology, uses AI to optimize its chip design and manufacturing processes. The company employs AI models to predict thermal performance and optimize the placement of transistors on its chips. This has enabled NVIDIA to produce more efficient GPUs that deliver superior performance in gaming, AI, and data centre applications.

TSMC: AI-Enhanced Manufacturing

Taiwan Semiconductor Manufacturing Company (TSMC), the world’s largest dedicated chip manufacturing company, uses AI across its fabrication plants to enhance production efficiency and reduce defects. TSMC’s AI-driven predictive maintenance systems monitor the performance of critical manufacturing equipment, reducing downtime and ensuring consistent high-quality output.

The Future of AI in Semiconductor Design

As AI continues to evolve, its impact on semiconductor design and manufacturing will only grow. The integration of AI in the design and production pipeline is expected to reduce costs, improve chip performance, and shorten development cycles. Furthermore, as chip design companies push the boundaries of Moore’s Law, AI will play a pivotal role in developing innovative solutions to meet the increasing demand for computational power.

Top semiconductor companies are investing heavily in AI research, recognizing its potential to drive the next wave of innovation in chip design and manufacturing. From automating routine tasks to making complex design decisions, AI is set to become an indispensable tool in the semiconductor industry.

Conclusion

AI is revolutionizing the semiconductor industry, transforming how chips are designed, verified, and manufactured. By leveraging AI, top semiconductor companies, chip manufacturing companies, and chip design companies are overcoming the challenges of increased complexity and shrinking timelines. As AI technology advances, its integration into semiconductor design processes will lead to more efficient, powerful, and cost-effective chips, driving the next era of technological innovation. The future of the semiconductor industry is undoubtedly AI-driven, promising a world of smarter, faster, and more connected devices.

In summary, the integration of AI into semiconductor design and manufacturing processes is a game-changer for the industry. As top semiconductor companies and chip manufacturing companies continue to harness the power of AI, the future looks bright for continued innovation and growth. Whether it’s enhancing design accuracy, optimizing manufacturing, or streamlining supply chains, AI is proving to be a crucial driver of progress in the semiconductor world.