Innovative Approaches to Sustainability in Semiconductor Engineering

Have you heard that our digital world’s backbone, semiconductor engineering, is almost in a sustainable revolution? In addition to performance, environmental focus is very important for the growth of the semiconductor industry in current times, which has been pressured due to increased demand. As technology changes, so does the need for sustainability practices that reduce carbon footprints. These parameters can be achieved if the semiconductor industry, like other industries, conserves resources, and minimizes waste. This movement has become imperative for major semiconductor companies and other chipset manufacturing companies. Here, we will discover these trend-setting technologies in this area and what can be done with them to make a greener future in semiconductor engineering.

Circular Economy Model for Resource Efficiency

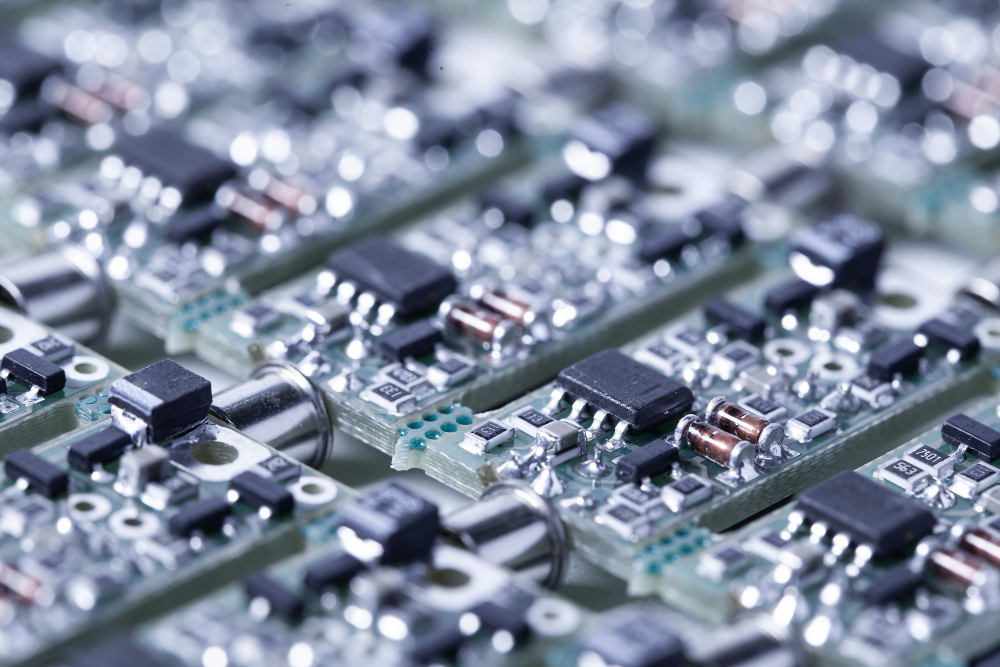

One of the most promising concepts for sustainability in semiconductor engineering is a shift to a circular economy. The conventional industrial practice of a linear economy involves the extraction, utilization, and subsequent disposal of resources. However, this approach is only feasible due to unrestricted resources and the emergence of environmental challenges.

Resource efficiency

The biggest semiconductor companies now focus on resource efficiency when planning their production activities. One can better manage resources by reusing and recycling materials. This would help in significantly reducing the need for newer ones. For example, extracting and refining raw materials such as rare earth metals is exploitative to the environment as it is energy demanding and poses serious environmental impacts. The recycling of such rare earth materials that form the crucial raw materials for the semiconductor industry should be promoted.

Incorporating sustainable principles

Incorporating more sustainable design principles into the process has made it more accessible to dismantle, repair, or upgrade components so that they remain functional for as long as possible. This move helps reduce waste, which would otherwise cause extra carbon dioxide emissions resulting from manufacturing new components. As such, the circular economy acts as one of the major pillars for sustainable practices within the sector, enabling resources to be used better and more responsibly, hence encouraging its adoption.

Efficient Manufacturing Processes

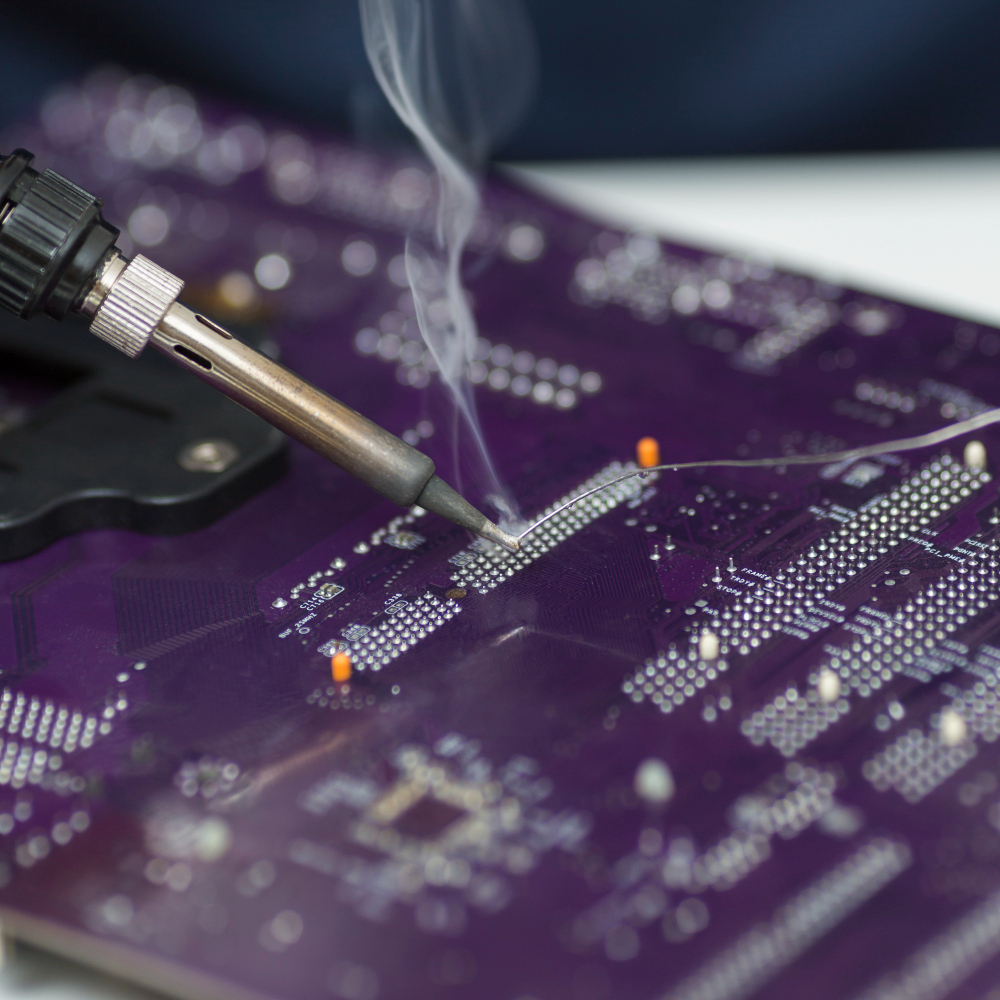

- Semiconductor manufacturing is notorious for its high energy requirements mainly because of electricity consumption in cleanrooms and machinery used in chip-making and cooling systems. The biggest semiconductor companies within this sector have recently invested in more efficient ways to reduce overall energy consumption significantly. These include highly advanced process nodes. This is also one of the most common approaches applied today, as many semiconductor manufacturers seek to achieve greater miniaturization and use less power during manufacturing. As a result, chips can be made with reduced power requirements, thus leading to lower energy needs by the entire industry.

- Moreover, major semiconductor companies are now increasingly investing in renewable sources of energy for their facilities in addition to process optimization. For instance, solar, wind, and hydroelectric power have been included in the semiconductor fab’s energy mix, thus largely reducing dependence on fossil fuels. Embracing these green energies in its operations will help keep greenhouse gas emissions low while ensuring that it generally supports sustained production within the semiconductor supply chain.

- Additionally, efforts are being made to minimize energy consumption in order to maintain the optimum operating conditions of semiconductor fabs. Due to higher energy requirements and their inefficiency, liquid cooling systems have been replacing conventional air-based cooling methods. In the move towards a more sustainable future, the semiconductor industry has accepted such energy-saving manufacturing processes.

This table offers a snapshot of how leading semiconductor companies are addressing sustainability through various initiatives, complementing the broader discussion in the blog.

| Company | Sustainability Initiative | Impact |

| Intel | Renewable Energy Adoption | Intel has significantly reduced its carbon footprint |

| TSMC (Taiwan Semiconductor Manufacturing Company) | Advanced Process Nodes | Lower energy consumption in production |

| Samsung Electronics | Green Chemistry Principles | Safer manufacturing processes |

| Texas Instruments | Closed-Loop Waste Systems | Reduced environmental impact |

| Applied Materials | Energy-Efficient Equipment | Reduced energy usage in semiconductor fabs |

| Micron Technology | Circular Economy in Materials Usage | Enhanced resource efficiency |

Blogs about the manufacturing process of semiconductors, such as how semiconductors are manufactured, are the best source of knowledge.

Minimizing Chemical Usage and Waste

Sustainability also impacts chemical use in semiconductor industry production. Semiconductors are made from many harmful chemicals to both people and the environment. Hence, chemical reduction and waste reduction are the chief focus of this sector.

One approach chipset manufacturing companies have adopted involves green chemistry principles. This entails developing new chemicals that are less harmful for manufacturing electronics. By substituting dangerous substances with safer alternatives, companies also enhance their safety records while protecting the environment. The other aspect concerns implementing advanced waste management systems, such as green chemistry, which helps reduce the environmental damage caused by semiconductor firms. These include wastewater treatment and recycling, capture and recovery of chemical vapors, and safe disposal of hazardous materials. Through reduced chemical usage and waste, the semiconductor industry is moving towards cleaner, more sustainable manufacturing processes.

Furthermore, waste minimization has become essential in process design. It involves optimizing chemical reactions so that by-products are minimized, increasing material utilization rates, and using closed-loop systems whereby wastes are recycled back into useful products. This helps lessen negative environmental impacts linked with semiconductor fabrication while ensuring cost reduction, resulting in both sides gaining something, i.e., achieving the environment conservation goal plus improving sector profitability.

Supply Chain Management in a Sustainable Manner

At every stage of the supply chain, those involved must thoughtfully and thoroughly address notable environmental concerns. This balance calls for the consistent upholding of conscious decision-making practices. Consequently, top semiconductor firms have shifted their focus towards embracing supply chain practices as a core element in sustaining their operations responsibly.

Another significant challenge for building a sustainable supply chain is ensuring all suppliers adhere to similar environmental principles. This necessitates stiffer checks on and better monitoring of such suppliers by conducting audits regarding their implementation of sustainable practices as they do their business. For instance, carbon emission reductions by avoiding transporting raw materials during extraction and manufacturing processes can be achieved through cooperation between suppliers and producers in the semiconductor industry.

Furthermore, there has been a surge in demand for ethical sourcing within this market segment. This refers to avoiding conflict minerals from areas where their extraction might worsen human rights abuses. As such, several major semiconductor companies have vowed never to use these materials as a way of promoting green living and corporate ethics.

Conclusion

The Semiconductor industry has reached a crucial junction that demands more than being an option; hence, it is obligatory. Furthermore, major semiconductor companies in this business have already been pioneering new sustainability thematic areas, such as incorporating a circular economy, improving energy efficiency, reducing chemical reliance, and sustainable supply chain management. These benchmarks will influence the environmental friendliness of the semiconductor manufacturing process and, therefore, set new records for the whole sector. Consequently, as its technology advances, so should the semiconductor industry ensure that its products are environmentally friendly due to their performance and other associated factors.

Ready to accelerate your innovation? Contact NanoGenius Technologies for state-of-the-art ASIC design, FPGA prototyping, and comprehensive verification services. It is time to turn ideas into reality with our expert solutions. Let’s push the boundaries of what’s possible—contact us today to start your next project!